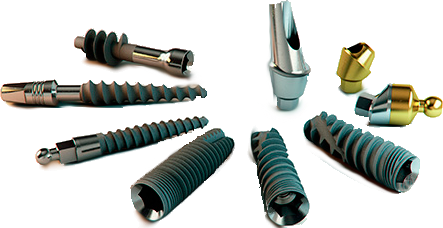

Measuring dental implants in production: how to face the challenges of a high potential market. The dental implant market is characterized by a complex product that requires several controls.

However it is precisely this level of control which qualifies the manufacturer and distinguishes him from his competitor.

1. What opportunities would you have with a 100% control of the implants at extremely reduced prices?

2. How much would your production increase by reducing the control time to just a few seconds?

After a careful analysis of these requirements, VICIVISION has created a product that gives a whole new meaning to dental implants: MTL X5.

Complete

MTL X5 carries out external dimensional controls on the diameter, length, angle, radius, throat, thread, hexagon faces, coaxiality, circularity, cylindricity of the stem, etc. in a single cycle which lasts only a few seconds, reduces costs and puts you ahead in the competitive challenge.

Flexible

MTL X5 allows you to pass from one batch to the next in a matter of seconds, by the simple click of a mouse and with no setting required to improve the margin of the split orders, a typical feature in the dental implant sector.

Efficent

MTL X5 gathers all the data automatically for statistic controls in order to monitor any changes in the measurement, to prevent rejects and to produce control certificates that may be presented to your clients along with the product as a further guarantee of quality and assurance.