TECHNO SERIES

For shafts up to 1250 x 180 mm

A modular range can provide the most suitable machine for your production.

Maximum performance combined in 20 measuring ranges:

from 40 x 180 mm up to 300 x 1250 mm.

PRIMA SERIES

The optical measuring machine for all CNC lathes.

PRIMA From 60 to 140 mm of diameter, from 300 to 600 mm of lenght.

X SERIES

For micro components

An exclusive solution in the sector.

Specific for micro-mechanical parts, watch parts, dental and biomedical screws.

Maximum efficiency in measuring extremely minute and complex elements.

Unbeatable performance: the measuring system is now enriched with a Renishaw Scanning Probe.

Solutions for the quality control of specific applications.

Camshafts| Crankshafts | Dental and biomedical implants| Turbines | Valves.

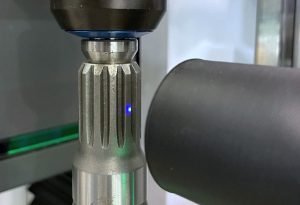

Check splined shafts in a few seconds with the new confocal system.