Řada Techno

Vyberte si na míru model z 20ti dostupných.

Tato řada měřicích strojů je navržena tak, aby se přizpůsobila současným a budoucím požadavkům výroby. Objevte širokou škálu nabízených rozsahů měření. Modulární řada řady Techno může poskytnout nejvhodnější stroj pro vaši výrobu. Od 40 do 180 mm v průměru a od 300 do 2000 mm na délku. VICIVISION nabízí evoluci profilového projektoru v kompaktní a rychlý optický měřicí systém s možností provozu přímo v prostředí výroby.

Stáhněte si zdarma průvodce Měření závitů

Pro výrobce je často obtížné získat přesné a objektivní výsledky při měření závitů. Někdy je obtížné změřit fittingy a válcované závity s různými rozměry závitů a je nezbytné mít obsáhlé sady kontrolních závitových kroužků. S nástrojem VICIVISION Thread Tool může jediná softwarová funkce během několika sekund automaticky měřit fittingy a soustružené závity, jakožto i šrouby a trny.

Bezkonkurenční výkon kombinace optické a dotykové metody

VICIVISION poskytuje zcela novou měřicí funkci pro hřídele kombinující specifickou metodu optického know-how s měřicím systémem Touch Probe.

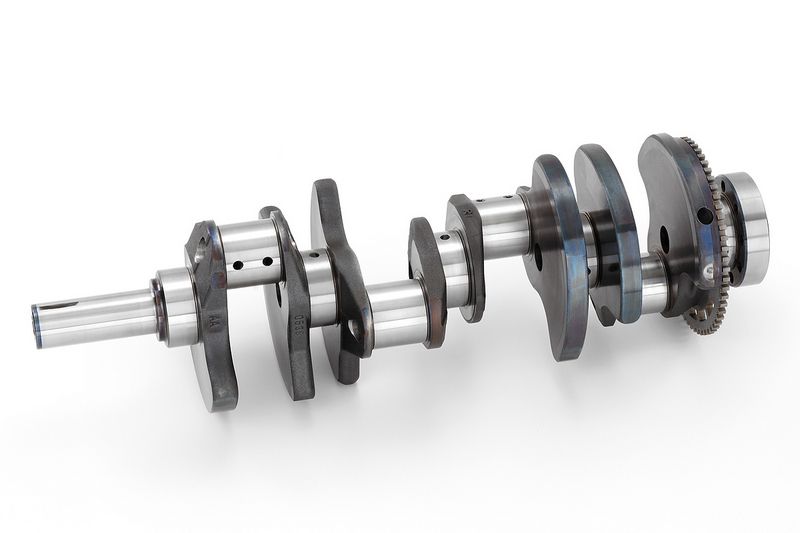

Ideální pro měření klikových hřídelí

Výrobci hledají flexibilní řešení, aby udrželi krok se zvýšenou variabilitou produktů. Flexibilní, přizpůsobivý a všestranný.

Společnost VICIVISION vyvinula specifický softwarový nástroj určený k měření klikových hřídelí přímo ve výrobním prostředí.

Zvyšte svou produkci.

VICIVISION přináší kontrolní zařízení na místo, které nabízí největší výhodu: přímo ve výrobě. Každou součást vyrobenou na CNC soustruhu lze měřit ve výrobním prostředí. Což znamená vyšší produktivitu i u menších sérií: výměna dávky je rychlá a efektivní.

Měření soustružené součásti, budoucnost soustružení.

Automobilový průmysl, letecký průmysl, stavebnictví, elektro a deriváty techto odvětví, lékařství, ropa a plyn, jsou jen několika předními odvětvími přitahující zahraniční investice. Příležitosti a výzvy jsou na každém rohu: rostoucí poptávka, stále vyšší požadavky brány jako „standart“, změny směrem k digitálním, dokumentovaným a včasným dodávkám, konkurenční tlak. Aby se výrobní podniky mohly v tomto obchodním prostředí pohybovat, je třeba si uvědomit, že čas a výstupy kontroly ovlivňují výsledné výrobní náklady.

Jeden měřicí systém schopen obsloužti více CNC soustruhů.

Jediný měřicí systém může pracovat vedle více obráběcích center a zahrnujících více než jednoho operátora.

Vyrobte více se stejným počtem CNC soustruhů.

Produkovat více znamená zvýšit efektivitu. Znamená to využít svůj potenciál naplno.

Svou produktivitu můžete zvýšit bez dalších investic:

stroj zahrnuje funkci profilprojektorů, optických komparátorů, kalibrů, závitových kroužků, výškoměru a dalšího metrologického vybavení.

Udržování výroby v mezích tolerancí.

Snížení prostojů výrobního stroje díky okamžité kontrole bez nutnosti operátora opouštět pracovní stanici.

s VICI lze implementovat preventivní akce díky indikovacích grafů, trendů měření, abyste dosáhli významného snížení počtu zmetků.

Operátor může vidět, které hodnoty se brzy stanou mimo toleranci, a analyzovat je v průběhu času. Bude schopen proces výroby korigovat dříve, než to dosáhne hranice toleranci, či ji překročí, což při nutnosti pozdního zásahu způsobí prostoje výrobního stroje.

Cílem optického měření není jen měření, ale také udržení výrobních dílů v toleranci, zabránění prostojům výrobních strojů.

VICIVISION Tool-loop.

Existuje možnost nastavitelného rozhraní mezi systémy VICIVISION a výrobní stanicí. Pomocí které lze se automaticky zasílat korekční data obráběcího nástroje. Tato funkce eliminuje lidskou chybu a zrychluje nastavení parametrů nástroje. Každá vyrobená součást je tedy vyrobena v toleranci a připravena k expedici.

Optické měřicí zařízení, které zvyšuje produktivitu.

Operátoři výroby jsou během inspekce nezávislejší. Nastavení ofsetu obrběcího nástroje lze upravit dříve, než se součásti dostanou mimo toleranci, aby se snížilo množství vytvářeného odpadu.

Špičkový software

Zcela nová verze MTL 8.10 je navržena tak, aby zlepšila fázi kontroly a dále rozšířila počet možných měření. Zahrnuje specifické nástroje pro statická a dynamická měření a speciální nástroje pro matice, závity, vačkové hřídele, turbíny atd.

Pokročilé funkce softwaru

Nové automatické funkce pomáhající operátorovi k měření: automatické programování, automatické načítání programu součásti, programování s asistencí krok za krokem, srovnání DXF.

Měřicí reporty

Tento software umožňuje operátorovi tisknout nebo exportovat úplné a vlastní reporty o měření ve formátu PDF. Výsledky měření na histogramech k okamžité konzultaci.