M2 – M3

Measuring big shafts as easily as small ones

Optical measuring instruments for turned parts inspection.

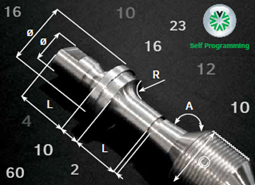

The M2 and M3 metrology equipment were born to assist in production. Designed not only to measure large shafts, they can also capture minute details such as bevels and small radii.

A top end machines measuring from small components to 140x900mm shafts.

VICIVISION M2 and M3 vision systems provides an increased load capacity allows elements up to 250 mm in diameter to be positioned.

Increased production

- Inspections in a matter of seconds, programs in just minutes

- Operators are more independent during inspection.

- Avoid machine downtimes even if tolerances are tight.

- Ensure zero defects thanks to frequent inspections.

Measurements Reports

- With the VICIVISION metrology instrument, measurement is not influenced by manual intervention.

- It allows to set tool offset before values are out of tolerance.

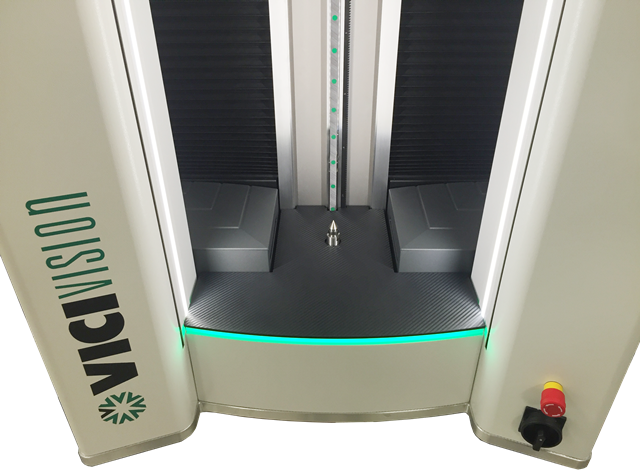

Working area

The live image of the shaft displayed by the metrology software, combined with the LED illuminated extensive working area, gives a clear vision of the profile conditions of the component being measured.

The retractable sensors enabled during loading and unloading provide reinforcement, with additional one of a kind protective bumpers.

Ergonomic design

The ergonomic piece clamping lever has a considerably wide grip, which is suitable both for left and right-handed operators, and prevents obstruction of the view when clamping or unclamping the piece.

GALLERIA FOTOGRAFICA

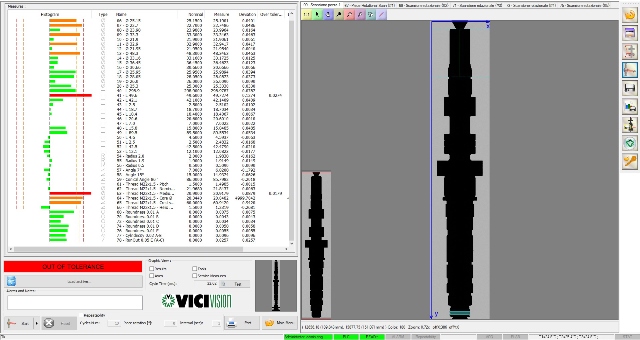

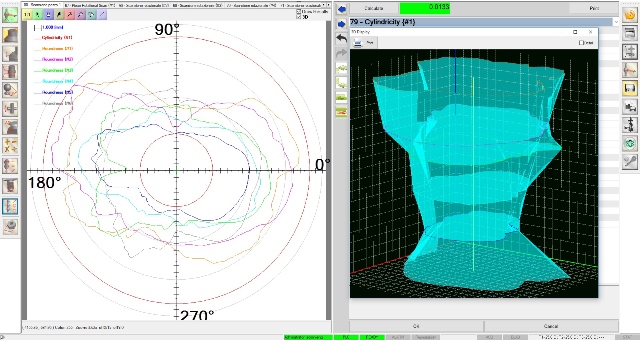

Cutting-edge software

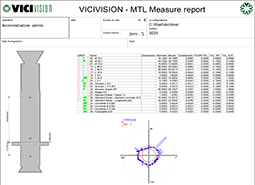

The brand new MTL 8.10 version is designed to improve the control phase and further extend the number of possible measurements. It includes specific tools for static and dynamic measurements, and dedicated tools for threads nuts, camshafts, turbines, etc.

Advanced software features

New automatic features help the operator to get measurements: self-programming, automatic loading of the part program, step by step assisted programming, DXF comparison.

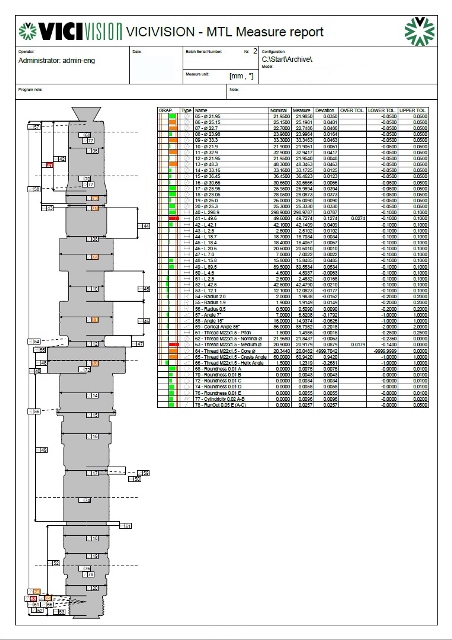

Measurements report

The software allows the operator to print or export complete and custom pdf measurement reports. Results of measurements on histograms for immediate consultation.